Flange Tensioners

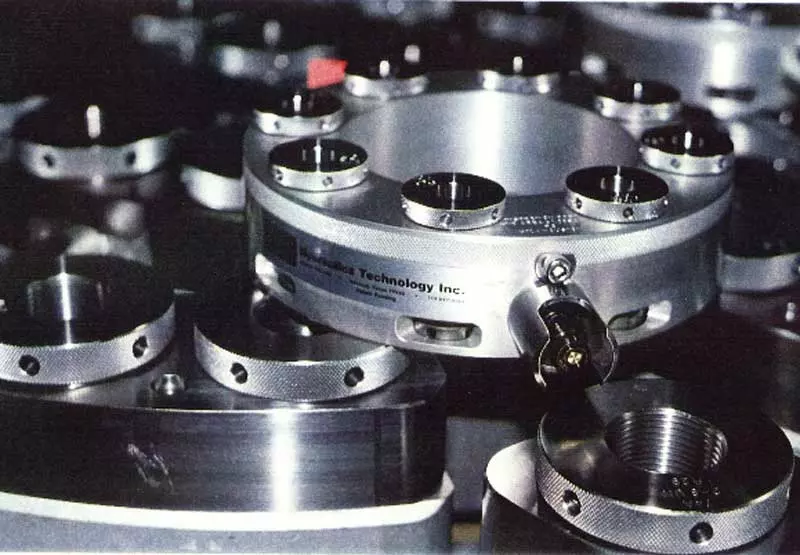

Hydraulic tensioning is the ideal method for tightening bolted connections. Hydraulic tensioning eliminates inaccuracies and helps achieve correct bolt loading in critical connections. At HTI, we’ve been building hydraulic tensioners and nuts since 1986.

What is a Flange Tensioner?

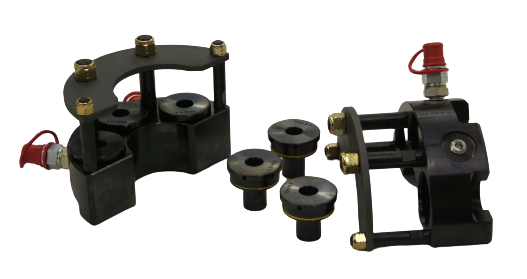

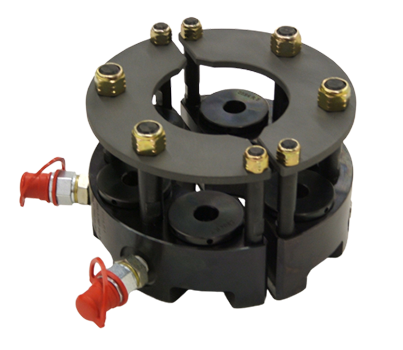

Flange tensioners are often called split-ring tensioners as they come in two or more pieces meant to operate together and form a complete ring once assembled on the flange.

HTI's standard hydraulic tensioners are designed to fit most ANSI and API flanged connections; you can certainly use our standard tensioners with flanges. When tensioning systems with multiple studs, even loading in each stud is important. This is especially true in applications with gaskets, such as flanges.

With HTI's flange tensioners, this can be achieved easily with a (typically) two-piece system that easily fits around the pipe and tensions all flange simultaneously.

Uniform Stud Loading

Even loading in each stud is important, especially in applications with gaskets. HTI recommends multiple hydraulic stud tensioners for applications with more than one stud. These hydraulic tensioners are inner connected to each other and to the pump. As the hydraulic pressure increases, the tension in each stud is the same, and the flange comes together simultaneously and evenly.

Flange tensioners also work well with compact flanges that don’t leave enough room for a traditional tensioner. They also reduce the cycle time for tensioning a flange connection as all tensioning is done in a single operation, vs many for a single tensioner.

Similar Products

Fixed Tensioners

Learn More

Variable Tensioners

Learn More

Single Stage Tensioners

Learn More

Multi-Stage Tensioners

Learn More

Foundation Tensioners

Learn More

Through-Hole Tensioners

Learn More

High Load & High Stroke Hydraulic Tensioners

Learn More

Multi-Unit Tensioners

Learn More

Large Stud Diameter

Learn More

Subsea Tensioners

Learn More

Wind Turbine Tensioners

Learn MoreCustom Engineered Tensioners Since 1986

HTI has been designing engineered solutions to your toughest bolt tensioning problems since 1986! You can choose from one of our standard catalog sizes above, or we can design a custom fixed tensioner for any application when a standard model won’t work. HTI tensioners can be designed for imperial or metric-sized studs, high loads, high temperatures, large stud sizes, or corrosive environments. Our multi-unit tensioning systems can make easy work of large bolted systems, and our automated tensioning systems can reduce labor and increase throughput in high-volume manufacturing applications. Contact us to start the process of getting the right tensioning solution for your flange or any other application.