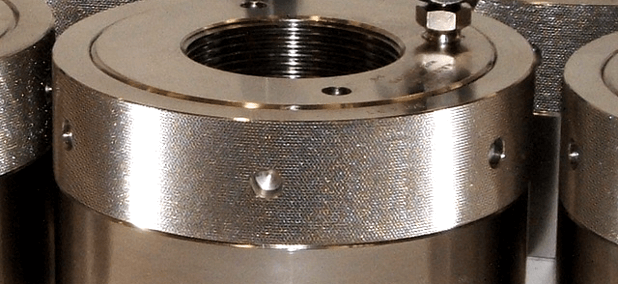

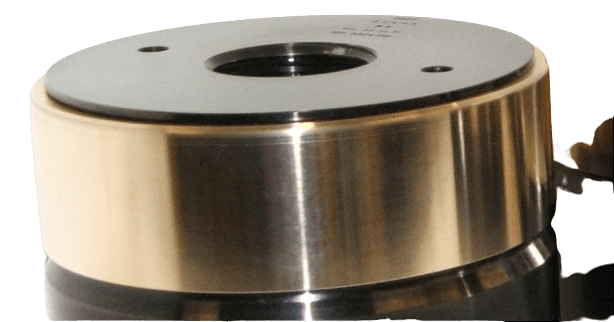

Hydraulic Tensioning Materials, Coatings, and Finishes

Hydraulic tensioning is the ideal method for tightening bolted connections. Hydraulic tensioning eliminates inaccuracies and helps achieve correct bolt loading in critical connections. At HTI, we’ve been building hydraulic tensioners and nuts since 1986.

HTI offers a variety of hydraulic tensioner materials, coatings, and surface finishes on our hydraulic tensioners and hydraulic nuts.

Custom Engineered Tensioners Since 1986

HTI has been designing engineered solutions to your toughest bolt tensioning problems since 1986! You can choose from one of our standard catalog sizes above, or we can design a custom fixed tensioner for any application when a standard model won’t work. HTI tensioners can be designed for imperial or metric-sized studs, high loads, high temperatures, large stud sizes, or corrosive environments. Our multi-unit tensioning systems can make easy work of large bolted systems, and our automated tensioning systems can reduce labor and increase throughput in high-volume manufacturing applications. Our engineers are happy to consult with you to help choose the right finish for your hydraulic nuts.

Similar Products

Standard vs. Spring Return

Learn More

Single stage, Multi-Stage, and Elliptical Tensioners

Learn More

Through hole tensioners

Learn More

High Stroke Tensioners

Learn More

Gearbox

Learn More

Fixed vs. Variable Tensioners

Learn More

Overstroke Indicator & Stop

Learn More