Hydraulic Pump Coupling Tensioners

Hydraulic tensioning is the ideal method for tightening bolted connections. Hydraulic tensioning eliminates inaccuracies and helps achieve correct bolt loading in critical connections. At HTI, we’ve been building hydraulic tensioners and nuts since 1986.

What are Pump Coupling Tensioners?

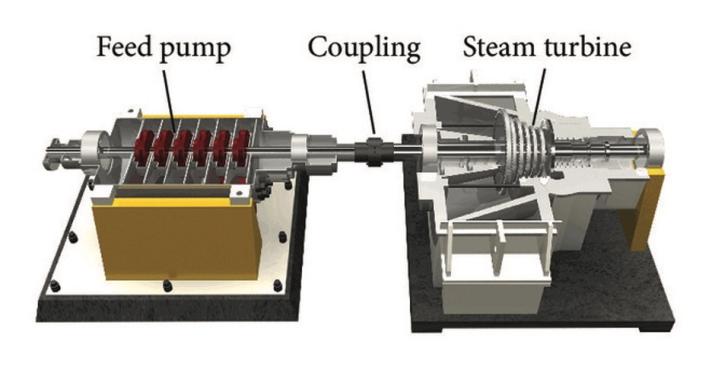

Traditionally, installing and removing coupling flanges on tapered shafts has been accomplished by heating the flange or by using a jury-rigged assortment of mechanical jacks. These methods are time-consuming and can be a safety hazard.

To avoid these methods, HTI has developed our very own Pump Coupling Tensioners, which allow you and your team to install and remove coupling flanges in a fast, accurate, safe, and cost-effective way.

Pump coupling tensioner with backing plate

Pump Coupling Tensioner Applications:

HTI's coupling hydraulic tensioners can be used for a number of applications. Below are a few common applications of using HTI's pump coupling tensioner.

- Condensate Booster Pump (CBP)

- Reactor Coolant Pump (RPC)

- Reactor Feed Pump (RFP)

- Reactor Recirculation Pump (RRP)

- Feedwater Pump

- Heater Drain Pump

- Steam Generator Feed Pump (Both Main & Auxiliary Pumps)

- Any Primary or Secondary Pump with a Tapered Shaft

- Any Piece of Rotating Equipment with a Tapered Shaft

Thread the Pump Coupling Tensioner onto the tapered shaft. Connect the hose assembly and the hand pump, then increase the pressure to push the coupler flange to the desired location on the shaft.

Thread the opposite end of the Pump Coupling Tensioner onto the tapered shaft. Install the Backup Plate for the Tensioner to push against. Attach the hose assembly and the hand pump, then increase the pressure to push the flange off of the tapered shaft.

- Allis-Chalmers

- Bingham Willamette

- Byron Jackson

- CE–KSB

- DeLaval

- Gould

- Ingersol Rand

- Johnston

- Pacific

- Sulzer

- Sulzer Bingham

- Westinghouse

- Worthington

We also offer hydraulic pumps to help transfer liquids into hydraulic systems.

Similar Products

Fixed Tensioners

Learn More

Variable Tensioners

Learn More

Single Stage Tensioners

Learn More

Foundation Tensioners

Learn More

Multi-Stage Tensioners

Learn More

Through-Hole Tensioners

Learn More

Flange Tensioners

Learn More

Subsea Tensioners

Learn MoreCustom Engineered Tensioners Since 1986

HTI has been designing engineered solutions to your toughest bolt tensioning problems since 1986! You can choose from one of our standard catalog sizes above, or we can design a custom fixed tensioner for any application when a standard model won’t work. HTI tensioners can be designed for imperial or metric-sized studs, high loads, high temperatures, large stud sizes, or corrosive environments. Our multi-unit tensioning systems can make easy work of large bolted systems, and our automated tensioning systems can reduce labor and increase throughput in high-volume manufacturing applications.