Wind Turbine Hydraulic Tensioners

Hydraulic tensioning is the ideal method for tightening bolted connections. Hydraulic tensioning eliminates inaccuracies and helps achieve correct bolt loading in critical connections. At HTI, we’ve been building hydraulic tensioners and nuts since 1986.

What are Wind Turbine Bolt Tensioners?

Hydraulics Technology offers hydraulic stud tensioning solutions for the wind turbine industry.

Our wind turbine hydraulic tensioners are used for fastening applications from the blades, through the nacelle and tower to the foundation studs. Our wind turbine tensioners and equipment are tried and true, and are extremely reliable for tensioning critical joints.

Single and multi stage tensioners for wind turbine applications

Engineered and Field Tested for your Wind Service Applications

HTI’s Wind Turbine Tensioners have been designed by our team for a variety of renewable energy wind turbine bolting applications.

Hydraulics Technology offers a wide range of customized solutions for your wind service bolting applications. We work with our customers from the very beginning of their projects to the very end. This process allows our team to custom design wind turbine bolting solutions to perfectly suit their job/application.

Our custom solutions set us apart from our competitors, and we manufacture tensioning kits for most major wind turbine manufacturers.

Contact our Engineering Team today to discuss the wind tensioning solution you need today.

Features of Wind Turbine Tensioners

Our Single and Dual-Stage Wind Turbine Bolt Tensioners offer a number of features, including:

- Lightweight and compact

- Automatic piston re-stroking, over-stroke protection and gearbox nut rundown

- Swivel 90º Elbow connections are also available

Durable and Secure Wind Turbine Bolts

Wind turbine hydraulic tensioners are a critical item in the proper functioning of any wind turbine. These tensioners are needed to tighten and tension the turbine’s bolts to their required torque.

HTI is not limited to one type of wind turbine bolting application. We offer Single-Stage and Multi-Stage tensioners that have been engineered for OEM Wind Turbines, including: Nacelle Frame Bolting, Blade Bolting, Tower Bolting (mid and upper sections), Bearing to Hub Bolting, Hub to Spindle Bolting, and much more.

HTI’s Wind Turbine Bolt Tensioners are being used across the wind service industry, and for good reason. Our customized solutions are applicable on a wide range of wind turbines, including, but not limited to:

- Siemens SG2.1 Wind Turbines

- Vestas V110 Model Wind Turbines

- Vestas V116 Model Wind Turbines

- Clipper Wind Turbines

- Mitsubishi Wind Turbines

- Williams Foundation Bolts

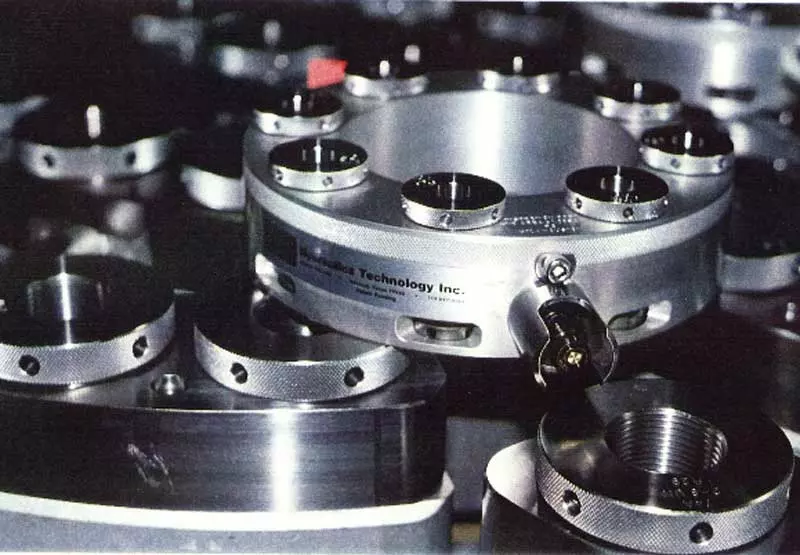

Wind turbine foundation stud tensioners with gearbox.

Wind turbine through-hole foundation stud tensioner with spring return.

Wind Turbine Bolting Applications

HTI's Wind Turbine Hydraulic Tensioners have been used to tighten various parts within the wind power industry, such as:

- Blade to Hub Bearing

- Front Foot to Base

- Base to Yaw Bearing

- Yaw Bearing to Tower Top

- Rotor to Gear Hub

- Hub to Main Shaft

- Tower Segment Flanges

- Foundation (Base Bolt) Studs

- Foundation Stud testing

Foundation Tensioners

Foundation stud tensioners for wind turbines often utilize a standard Hex Nut from the application as the reaction nut to tension the stud.

They feature a long working stroke (1”/25mm), have automatic piston re-stroking, and operate at 10,000 psi. High-Pressure Single and Dual-Stage Foundation Tensioners are also available.

Similar Products

Fixed Tensioners

Learn More

Single Stage Tensioners

Learn More

Multi-Stage Tensioners

Learn More

Variable Tensioners

Learn More

Foundation Tensioners

Learn More

Subsea Tensioners

Learn More

Flange Tensioners

Learn More

Multi-Unit Tensioners

Learn MoreCustom Engineered Tensioners Since 1986

HTI has been designing engineered solutions to your toughest bolt tensioning problems since 1986! You can choose from one of our standard catalog sizes above, or we can design a custom fixed tensioner for any application when a standard model won’t work. HTI tensioners can be designed for imperial or metric-sized studs, high loads, high temperatures, large stud sizes, or corrosive environments. Our multi-unit tensioning systems can make easy work of large bolted systems, and our automated tensioning systems can reduce labor and increase throughput in high-volume manufacturing applications.