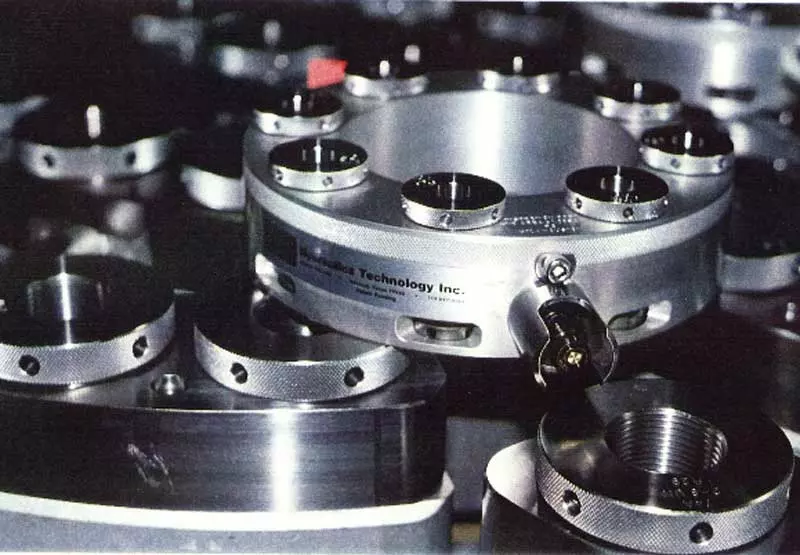

Extreme Temperature Hydraulic Nut

What is an Extreme Temperature Hydraulic Nut?

An extreme temperature hydraulic nut is a specialized type of hydraulic nut designed to operate efficiently under high temperature conditions up to 550 degrees celsius. HTI offers EziTite® hydraulic nuts that can withstand extreme temperatures beyond what our high temperature hydraulic nuts can.

Hydraulic nuts are tools used to apply a precise amount of tension to bolted joints. They work by using hydraulic pressure to apply a force to the nut, which in turn stretches the bolt to the desired tension. This method allows for accurate and repeatable loading of the bolt, which is crucial in applications where the integrity of the bolted joint is critical.

Extreme Temperature Hydraulic Nut Capabilities

What makes a hydraulic nut extreme temperature capable is its design and materials, which are selected to withstand the elevated temperatures found in certain industrial applications, such as power plants, oil refineries, and chemical processing plants.

These conditions can degrade standard materials and components, so hydraulic nuts for extreme temperatures are made with materials like high-grade stainless steel or alloys that maintain their strength, durability, and operational integrity at temperatures significantly higher than what standard hydraulic nuts can withstand.

To learn more, contact us today!

Custom Engineered Tensioners Since 1986

HTI has been designing engineered solutions to your toughest bolt tensioning problems since 1986! You can choose from one of our standard catalog sizes above, or we can design a custom fixed tensioner for any application when a standard model won’t work. HTI tensioners can be designed for imperial or metric-sized studs, high loads, high temperatures, large stud sizes or corrosive environments. Our multi-unit tensioning systems can make easy work of large bolted systems, and our automated tensioning systems can reduce labor and increase throughput in high-volume manufacturing applications.

Similar Products

Multi-Stage Tensioners

Learn More

Foundation Tensioners

Learn More

Through-Hole Tensioners

Learn More

Variable Tensioners

Learn More

High Load & High Stroke Hydraulic Tensioners

Learn More

Multi-Unit Tensioners

Learn More

Large Stud Diameter

Learn More

Flange Tensioners

Learn More

Subsea Tensioners

Learn More

Wind Turbine Tensioners

Learn More